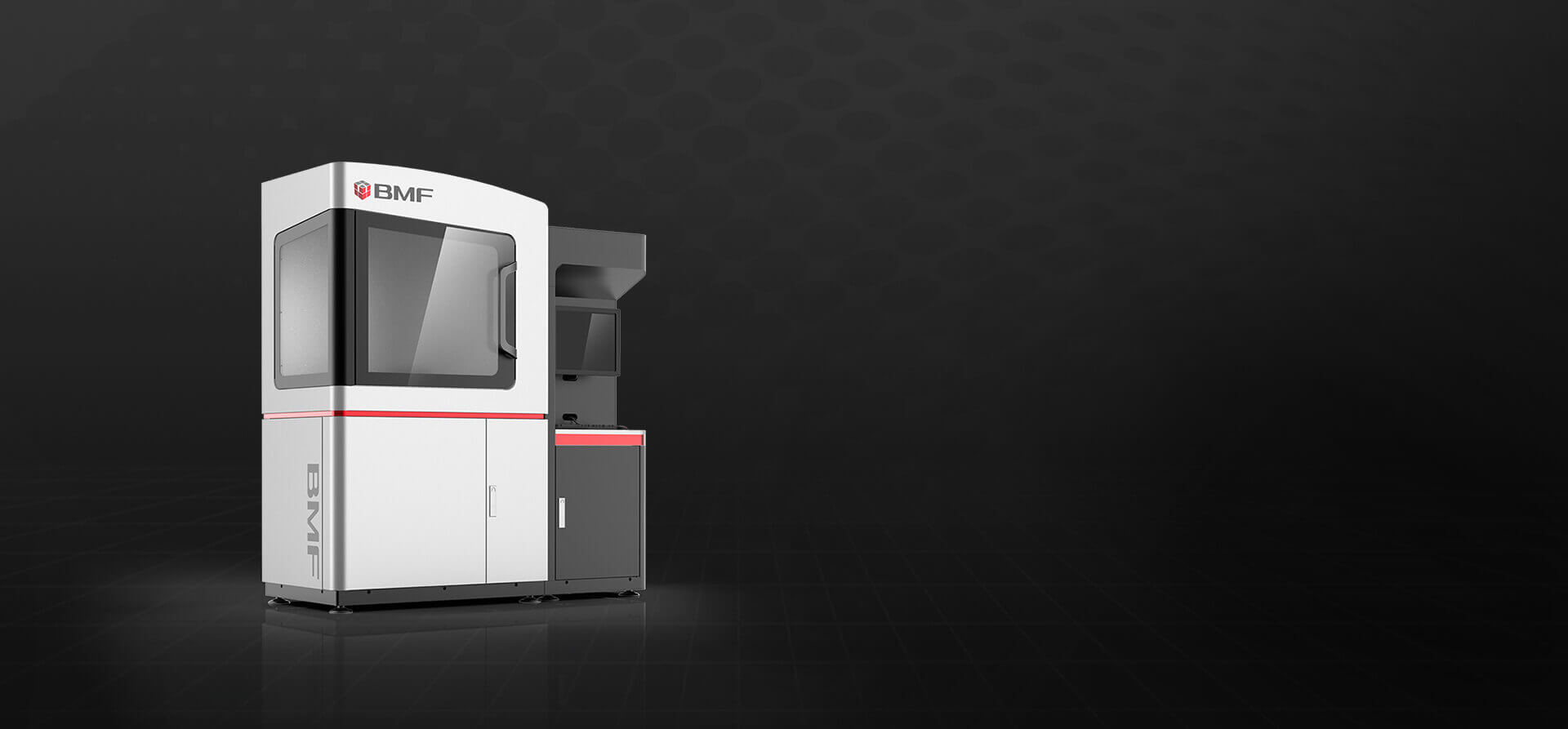

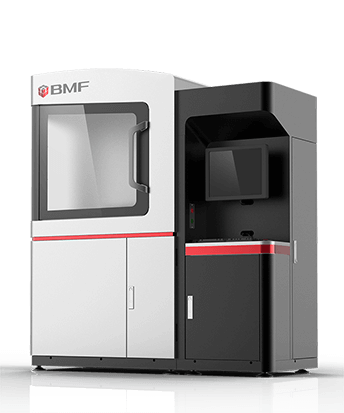

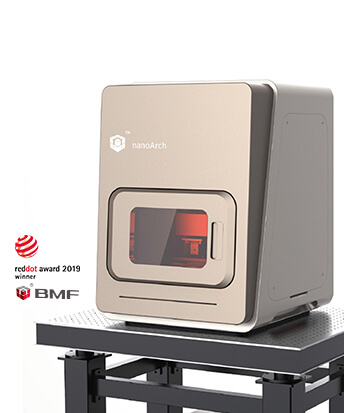

nanoArch P130

|

UV-LED(405nm) Light Source |

photosenstive resin Printing Material |

2um Exposure Resolution |

2μm~10μm in finestin typical XY Printing Resolution |

|

5μm~20μm in finestin typical Layer Thinkness |

3.84*2.16mm²*10mm in typical Printing Area |

2mm~10mm in typicalin Max Printing Height |

STL Input Data File Format |

|

3000w Power Supply |

1720(L)×650(W)×1820mm(H) External Dimensions |

450kg Total Weight |

|

Micro-scale 3D Printing System

Features

High resolution optical system and movement platform can be customized, with resolution down to 0.5μm.

Achieve both high resolution and large area through step-and-repeat process.

3D printed object with optical grade surface finish can be achieved through controlling the processing technology.

Real-time image monitoring, auto focus and exposure compensation.

Operation software with nanoArch graphic interface system and custom parameter setting.

Micro-scale 3D Printing System

Micro-scale 3D Printing System

References and Literature

After-Sales Services

Provide free operation guidance and technical consultations.

Repair repairable damaged parts, or debug malfunctions of the equipment.

BMF will respond and offer trouble-shooting solutions within 24 hours, and if necessary, send professionals to repair on site within one week.

BMF Precision Technology Co,Ltd.

BMF Precision Technology Co,Ltd.